Compatibility Management with Alterra

- Defining compatibilities between products

- Optimizing hit rate for suitable products

- Targeted filtering of data volumes

- Making expert knowledge available interactively

- Increasing sales of accessories and spare parts

Compatibility database for webshop and sales

Product configuration can be implemented using various methods. One method that is, among other things, suitable for combining components from different manufacturers is the so-called Compatibility Management. Using an intelligent set of rules, which is created in the background, allows to find exactly matching components and achieve the desired configuration result step by step.

Product configuration by finding compatible products or components

Nothing is easier today than ordering products on the Internet with a few clicks and getting them delivered immediately. For non-technical goods, the only criterion for the purchase is usually whether the customer likes the product or not. With electric household appliances, there are usually no problems with commissioning due to standardized connections. The reason for returning the goods here is usually simply the fact that the product in its real appearance does not live up to what a picture on the web has promised. The situation becomes even more problematic when it comes to technical products where there are different connections with different dimensions and the product therefore must fit functionally.

Example: Sanitary technology

Let’s take a sanitary engineer who has found the hose fitting required by the customer in a supplier’s web shop. Among other things, he is now looking for a suitable mating connection that he needs for installation. The craftsman must observe a number of selection criteria. To illustrate the problem, we show the selection of possible connection variants:

- Threaded pin with hole shape “W” (24°) according to DIN 3861

- Hose fitting D / N according to DIN 20 078

- Hose fitting E / P according to DIN 20 078

- Hose fittings according to DIN ISO 12151-2

- Valves and fittings according to ISO 8434-1 and ISO 8434-4

This list only reflects the possible standards for connections. Dimensions and other criteria are not yet considered. In short: there is a barely manageable number of possible compatible connections for the product. Finding the right part requires expertise and endurance. Without a doubt, the expert will find the right parts, either because he is working his way through the product specifications or because he uses the chat function that can now be found in many shops to consult with a specialist at the supplier’s.

It’s obvious that this approach takes up a lot of time and may lead to frustration. But what other options are there? Wouldn’t it be an unbeatable advantage if you could directly call up the exactly matching mating connections for the selected product?

Wanted: A system that shows compatible products immediately

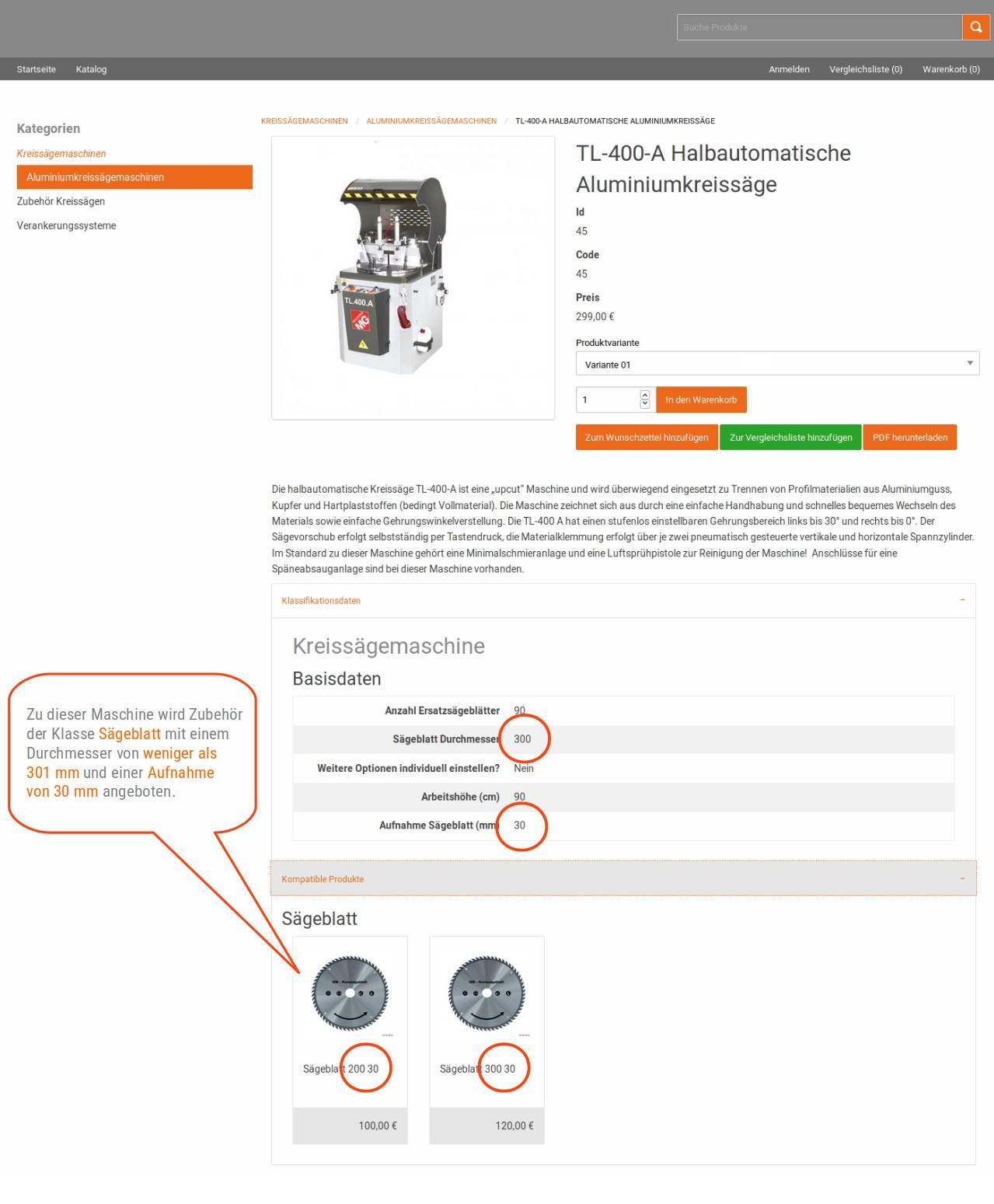

What is needed here is a smart search function that displays the compatible parts directly. If there are different connections to the product, the suitable parts should be displayed grouped by connection, if possible. In the webshop, a search result should then look like this: other products are displayed automatically that exactly match the selected product due to their specifications. Ideally, these should be all compatible parts available in the product pool in order to avoid creating “dead wood” from a logistics point of view.

Search and Find Compatible Parts and Accessories of a Produkt

Strategies for determining the search results

To achieve the search result shown in the above screenshot, there are several more or less promising approaches.

Strategy 1: Determination of compatible products via “Big Data / Crowd Sourcing”

The large Silicon Valley companies will probably advise to solve the issue via “Big Data”, i.e. to let as many users as possible find the suitable product via research and then offer their results to all other customers as “Suggested products list”.

Everyone who takes the time to think about it can imagine the disadvantages of this method:

Disadvantage 1: The full range of possible results will never be achieved. As soon as a customer has found the suitable product and this result is presented to the next user and evaluated as sufficient, no further suggestions will be added. The search result is virtually “frozen”. The lucky beneficiary of this procedure is the manufacturer whose product was the first to be found suitable. Sales of this product are skyrocketing, competing products will not be considered any longer.

Disadvantage 2: It takes large numbers of experienced customers, who over longer periods of time render “unpaid research services” to the shop operator. Most specialized traders will not – or at least not immediately – have the necessary user activity to generate the data required for this kind of data analysis. Information from users who have purchased products together is simply not available or determining this information would require years of operation of a webshop.

Strategy 2: Maintaining lists of suitable products

Another approach used in many webshops is that possible accessories or other products in the product pool are maintained directly “on the product” by the operator. This solution requires an effort by the shop operator: it is not the customer but experts at the supplier’s who define which products fit together.

Disadvantage: This approach requires a lot of labor and time and is additionally error-prone. Depending on the number of products in a shop, data maintenance can tie up immense capacities.

Disadvantage: The manual assignment of products to another product is in many cases impossible due to the enormous amounts of data.

Strategy 3: Definition of criteria for product compatibility

The approach that produces the best results is to define rules for the compatibility of products, which are then used by the webshop for evaluation. The properties of the connections can be used to determine precisely matching products. This solution also requires an effort by the shop operator or the manufacturers: It’s not the customer who determines which products fit together as with “Big Data / Crowd Sourcing”, but the experts.

Advantage: Through the intelligent definition of rules a data set of any size can be used as data source for filtering out the suitable parts.

Advantage: Once acquired knowledge can be multiplied and used for filtering information.

Prerequisites: Product knowledge is required to define compatibility, and intuitive software for data maintenance and analysis must be available to test the results directly. If suitable staff and the appropriate software for recording and evaluating the criteria are available, an unlimited number of products can be evaluated for compatibility with relatively little effort.

Which properties of the source product and target product are compatible?

For optimum results with respect to product or part compatibility, it must be possible to enter the basic data and the logics via an intuitive user interface. It must be possible to determine which properties of products fit together using the data entered. With the “Classification Management” and “Compatibility Management” modules, Sepia’s PIM System Alterra offers two tools that meet all requirements.

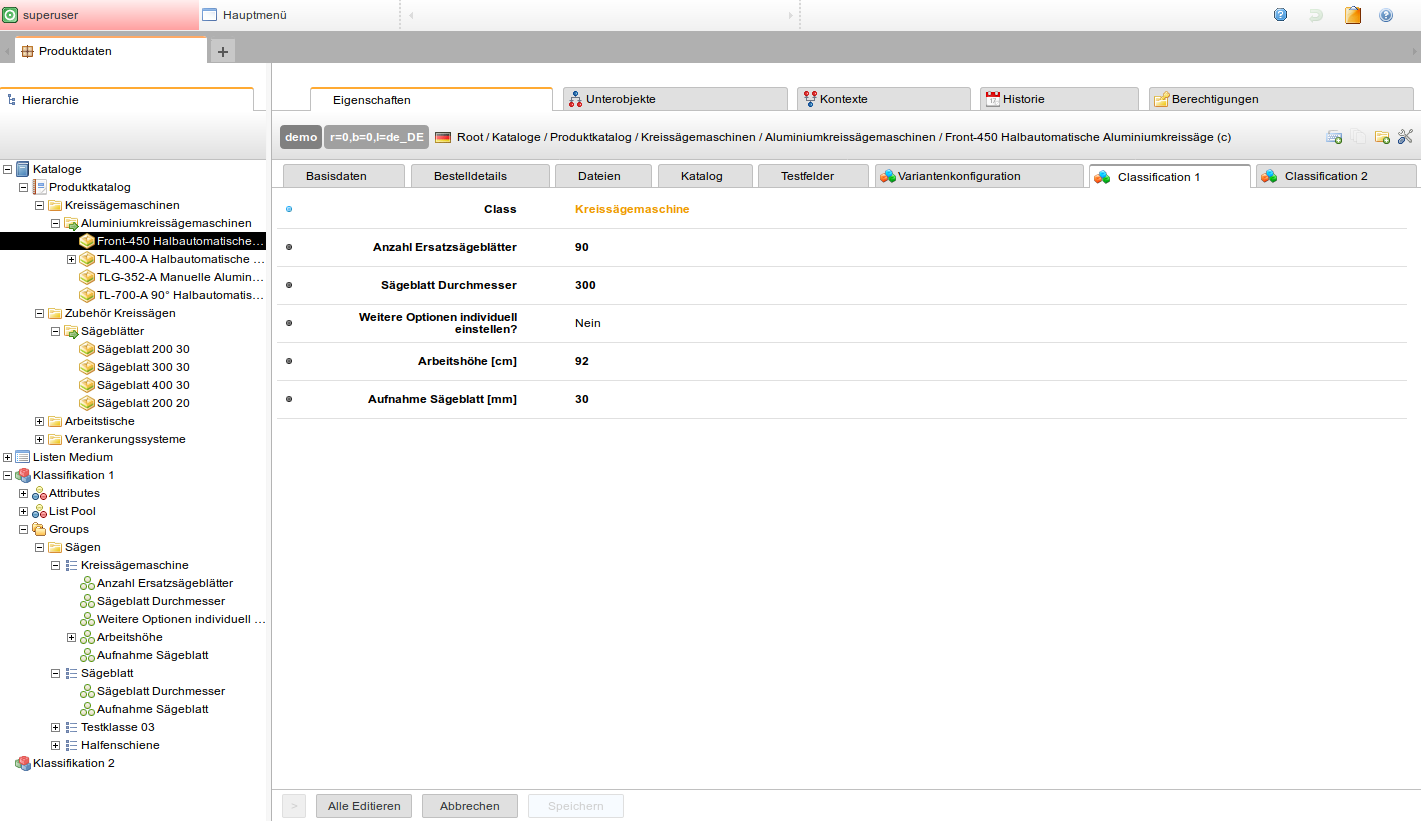

Source product

The condition is that all properties necessary for comparison with the accessory products must be entered on the source product.

Source: the source product for which suitable products are to be found using the rules.

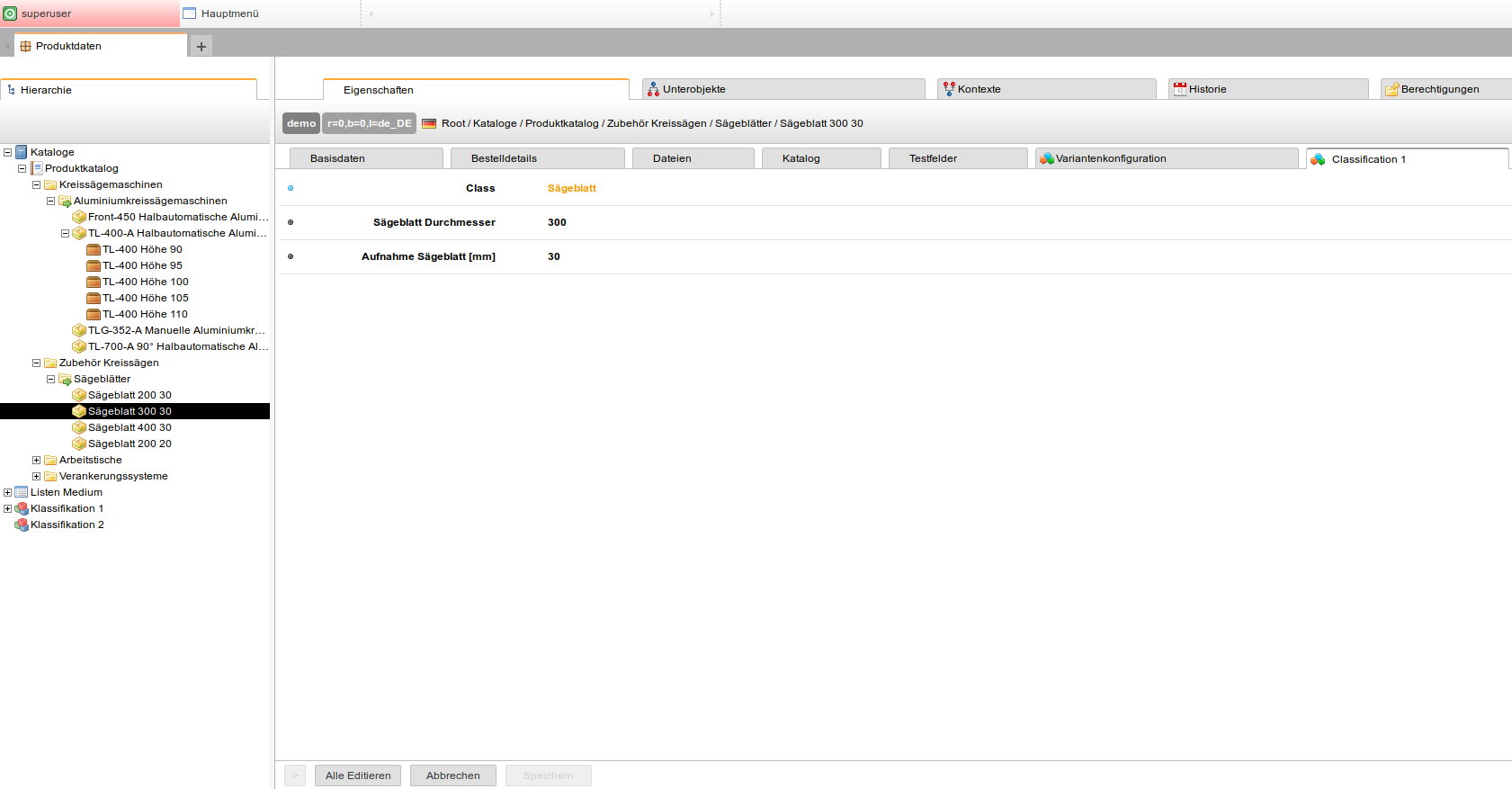

Target product

The proceedings for the target product are the same. Values that mark the connection between the products or parts must be maintained with particular care.

Target: the correct product found by the defined rules

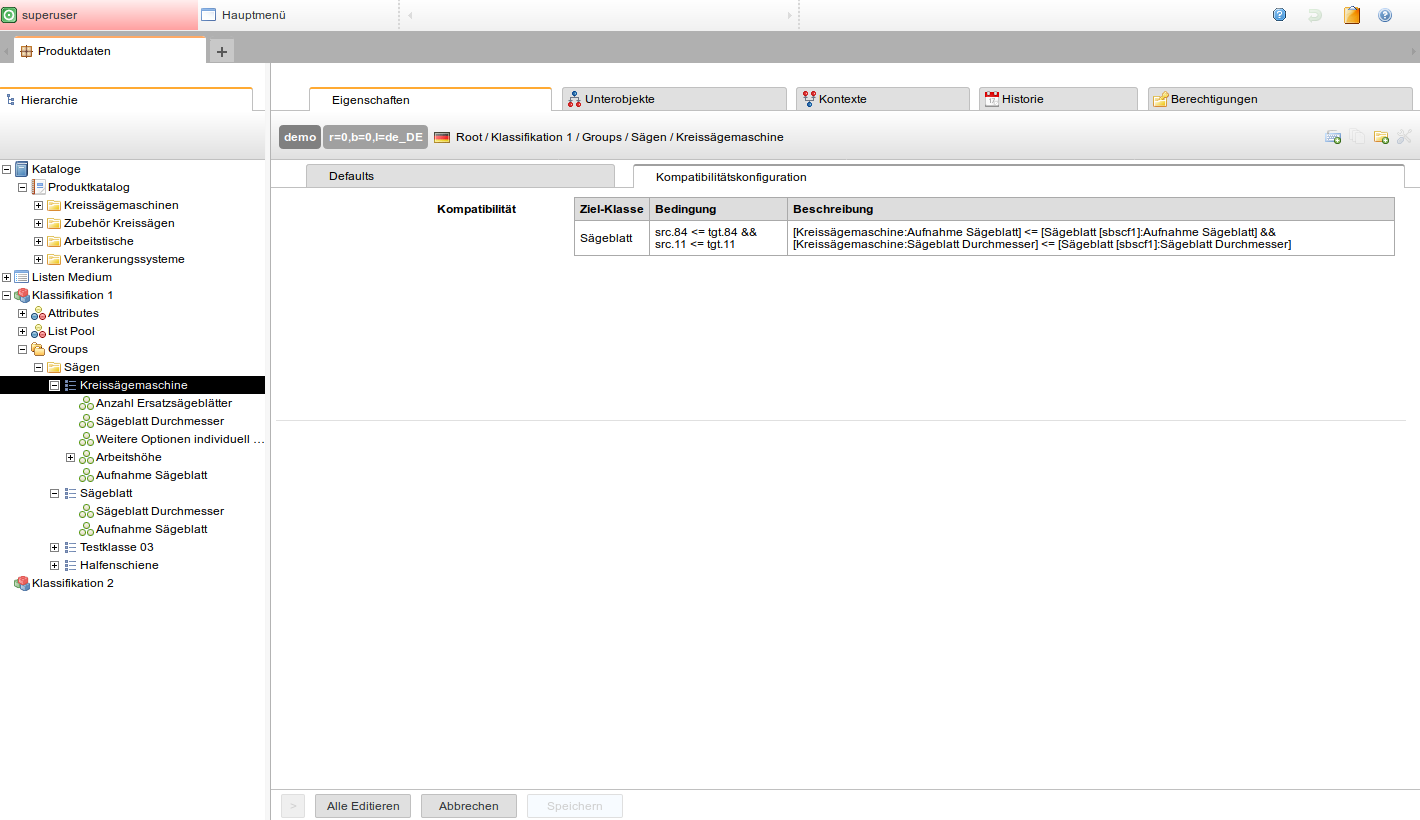

Definition of rules for the matching of product classes

Rules must be defined to establish a relation between the source and target products. If the rule applies, both products are displayed together.

Matching of Attributs

Practical examples

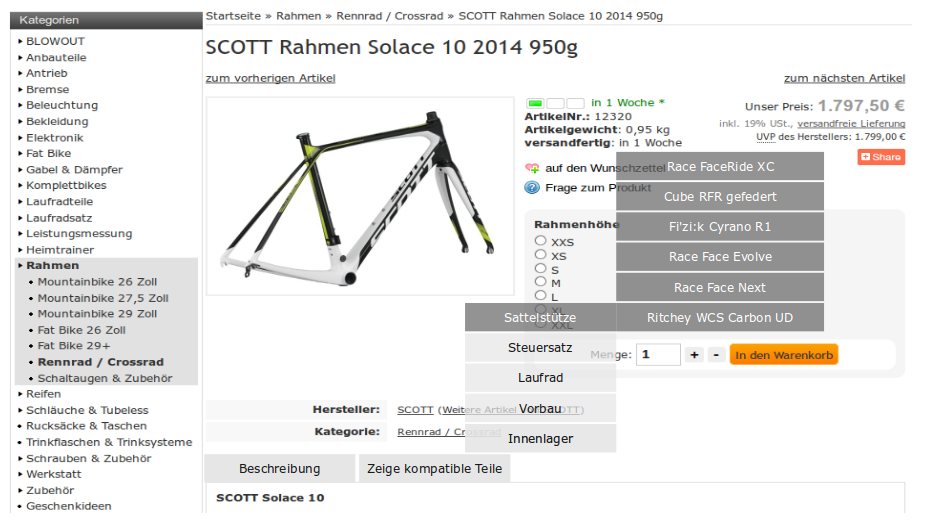

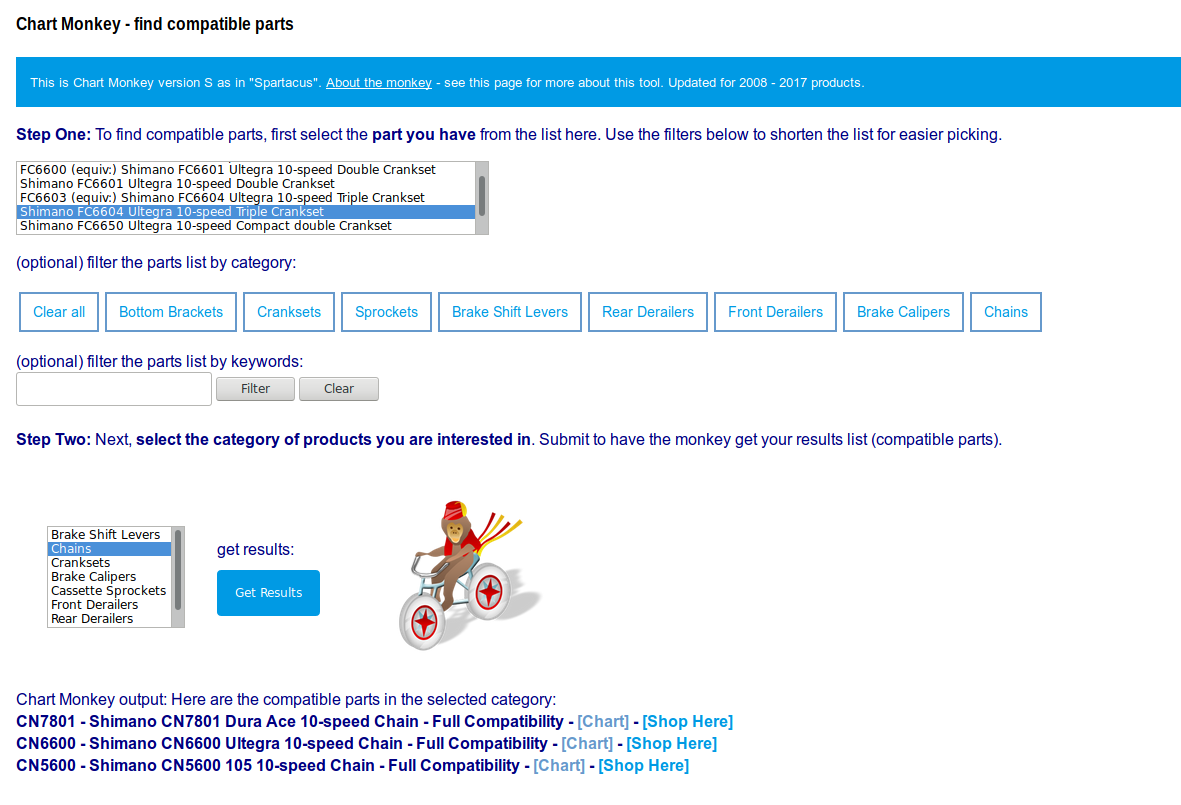

Bicycle Parts Finder

An easily understandable example of the sensible use of compatibility management is the bicycle industry. There is an “interface” for each component, where compatibility is required on both sides so that the parts fit together. Due to the large number of new products entering the market every year, the number of products to be recorded is very large – a manual 1:1 assignment of compatible products is therefore not recommended. This is where the method of defining compatibility via product properties used in Alterra comes into play.

Example for successfull ecommerce solutions: Webshop for bicycle components

Example: Webshop for bicycle components

Example for successfull ecommerce solutions: Part finder for bicycle componentskonfiguratoren

Example: Chart Monkey for Shimano bicycle components

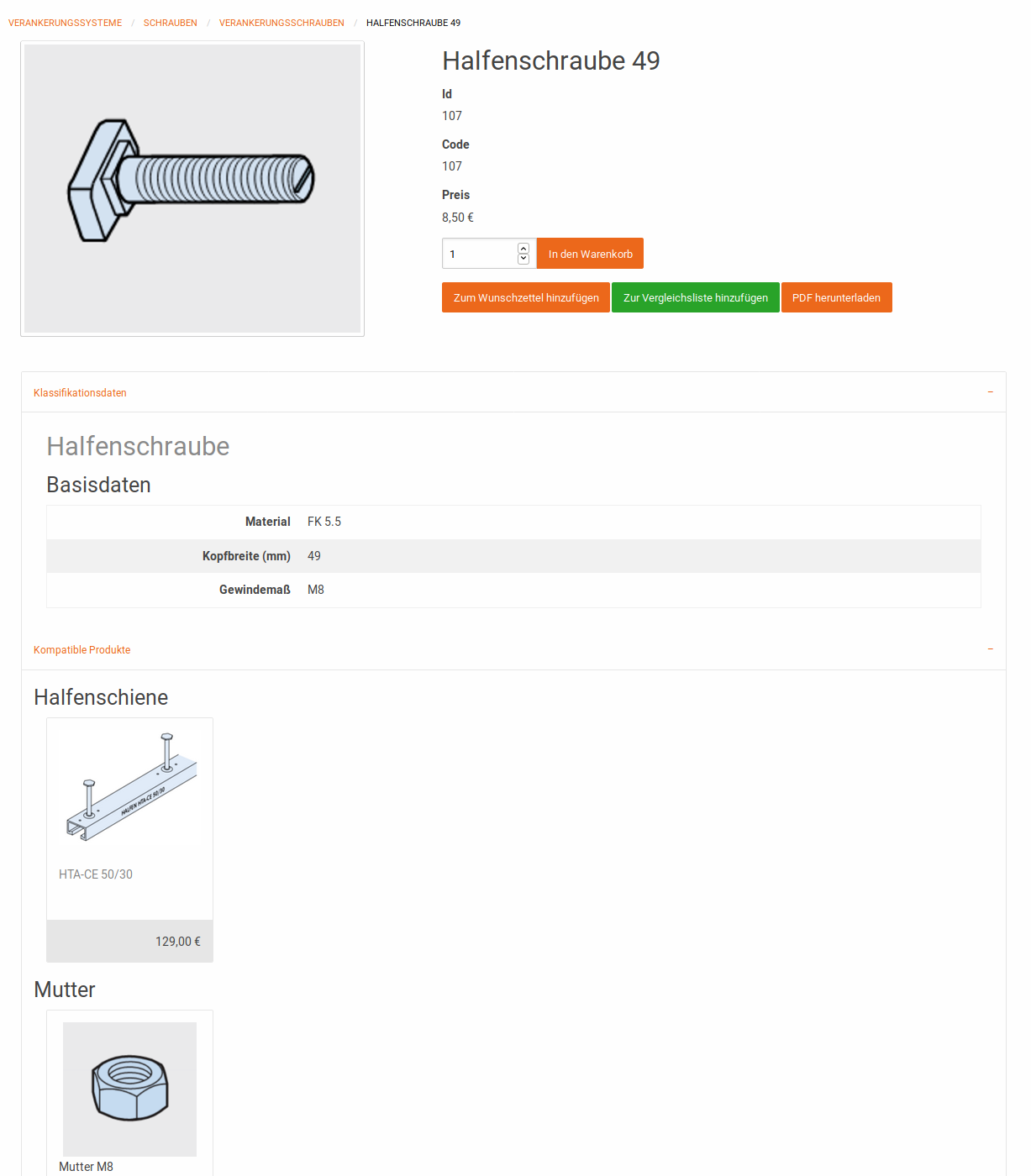

Construction components

Example “Parts for Construction”: HALFEN screw with head width 49mm and thread dimension M8 is compatible with HALFEN rail with internal dimension 50mm and nut with thread dimension M8.

HALFEN screw with head width 49mm and thread dimension M8 is compatible with HALFEN rail with internal dimension 50mm and nut with thread dimension M8.

Summary

Compatibility Management based on the definition of criteria for product attributes is the solution of the future. “Auxiliary constructions” such as the maintenance of mile-long compatibility lists or the currently hip “crowd sourcing” will lead in the medium term to unclean solutions and thus to dissatisfied customers. Systems such as Alterra, which efficiently record compatibilities and deliver the most precise results, are currently spreading on the market. Those who are among the early birds and partner with the right software provider will be able to secure significant competitive advantages.

Contact

Sepia GmbH & Co. KG

Ernst-Gnoss-Strasse 22

D-40219 Düsseldorf - Germany

Phone: +49 211 51 419 75

Phone alternative: +49 211 74 958 712 0

E-Mail: info@sepia.de

Looking for consultation or a web demo?

Get it here.